SOP: MSY: Walmart Shipping

Wal-Mart Shipping

Data Aquisition History

Walmart orders arrive to us from Simperal via FTP.

Gentran then imports the data and if it passes EDI Standards it then forwards it to COFS. The Gentran EDI Importing scheduler runs every 15 minutes. Gentran then exports a TDF file to the Farcmhnt1\Export\ folder. The file name should be i940xxx.tdf where xxx represents our client's 3 digit acronym from Accellos 1 (R)

Reportwriter Scheduler looks for the TDF and imports the data to the normalization database COFS utilizing the tables Pheader and Pdetail. With the data now normalized to a format which Accellos 1 can accept, Report writer then utilizes the program Acc1 Down Load to send the data to Accellos 1.

Accellos One Dnload function then Imports the data for visibility by our warehouse employees. This scheduler runs every 5 minutes last checked (01/28/2013)

Warehouse Employee's Processing of the Data

Step 1: Allocation:::

Once the orders are in Accellos 1 (c) the orders then need to be allocated for stock. Most important is the proper setting of the Zones and the printer to use. Zones can be somes just one zone or multiple zones. It depends upon where the product is located in our warehouse.

If you are utilizing multiple zones for let down of stock (ie Higher racks to lower Racks) and the settings for Replenishment are included in the zones which hold the additional inventory, the system will allocate and leave in the state of Waiting for Replenishment.

Otherwise Allocate and look if all the stock required is available or possibly it will go to Shorted state. If you are not worried about stock being shorted change the option on what should happen prior to hitting the submit button on the screen.

Assign a Handle prior to clicking submitt is to your advantage. Optimally it should be the trailer designation as predetermined by your processing of orders as groups. The handle can be a virtual trailer number or the actual trailer number if known. The handle only accepts 8 characters and is used as a grouping feature in Accellos(c)

Step 2: Waving vs. Faro Quick complete:::

Waving is the actual releasing of the order for picking. It produces pick tickets and the items must be scanned individually and assigned a carton ASN label. You can either ask for a new carton ASN label after each pick or you can tell the system prior to submit you need X amount of labels. Labels may not even be necessary. This is configuration issue. But keep in mind to properly send EDI for Wal-Mart each carton needs an ASN Number.

Faro Quick Complete will actually assign a new carton ASN automatically, thus taking the need to ask for labels out of the equation. Now if you are using Faro Quick complete and utilizing a Master BOL Number then read the SOP on Master BOL Generation before proceeding with Faro Quick Complete.

Waving Orders:::

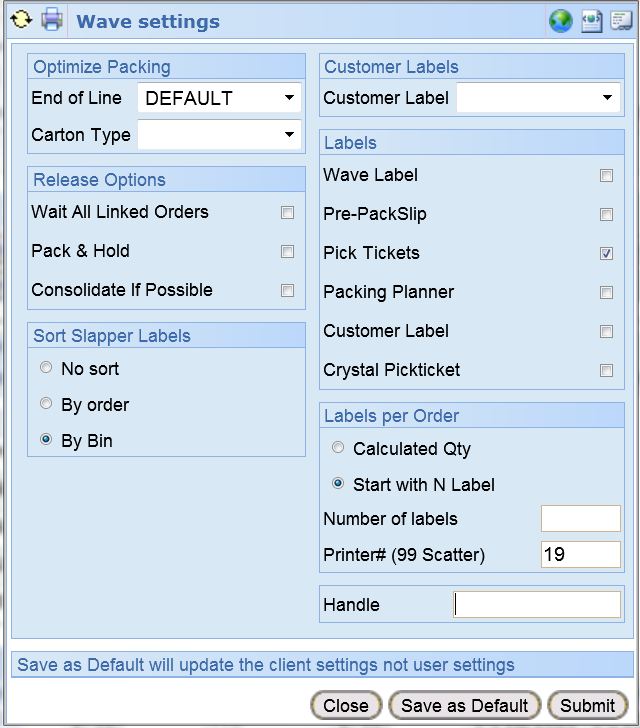

End of Line is normally preset. It will be normally 2 for MSY Orders

Carton Type: Should be empty

Release Options: Should all be blank

Sort Slappers labels: By Bin should be checked

Customer Labels: Should be blank

Labels: Pick Ticket should be the only one checked

Labels Per Order:

Start with N Label should equal your carton count

Printer Number should be your label printer Here it is set to printer 19

Handle : should be preset previously during the Allocation but can be changed at this time if necessary. Rembember that handles can only be 8 characters in length.

Click Submit upon filling out this form.

The order is now available for picking upon completion of the wave screen.

Faro Quick Complete Usage:::

Once the order is allocated the ability to use Faro Quick complete is available. This by-passes the wave process and generates a 1 to 1 label per carton. The order goes directly to rating. If you are utilizing a Master BOL see the SOP on Master BOL Generation prior to using Faro Quick Complete. Master BOL assignment is necessary for proper EDI if mutliple orders are being sent on the same trailer and must be assigned prior to Faro Quick Complete.

Wal-Mart Label Printing:::

IMPORTANT NOTE: Wal-Mart N of M labels will not print out using Faro Quick Complete. You must use the Label Matrix printing of N of M due to the required barcode embedded in the Carton Label.

The Wal-Mart Label is located in the J:\Labels\ folder. there are two reports. MSYWalMart and MSYWalMart_pdf. The ideal one is the MSYWalMart which actually generates the labels. Make sure your printer is properly set prior to printing.

The MSYWalMart_pdf uses the bullzip printer on the Terminal server and sends the output to a PDF file. This label should only be used if you are emailing the labels and is not a common type of output.

Shipping Orders Off the System:::

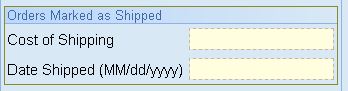

We need to enter the shipment date. It is recommended that you utilize the calendar button when ever possible for it checks your date for proper format before insertion into the Ship Date text box.

Cost okf Shipping is usually not a Faro Option to deal with but if known and is validated can be entered.

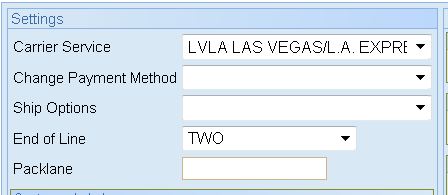

Shipping Settings are to be validated. Pick your Carrier and normally the End of Line will be preset for you before you enter this screen. Default is One. If there are any printouts required upon shipping then Packlane should be your HP or Canon Copier Printer Que. If you are not sure of the printer Que use the Custom Report in Accellos for Pack Lane Printers and find your printer. If it's not in there contact the IT dept. to update the report for you.

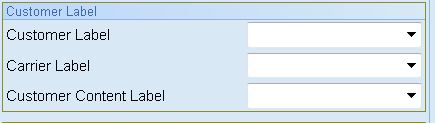

Customer Labels are usually not used. For Wal-Mart we currently do not have any labels to print at shipping time and should be left blank.

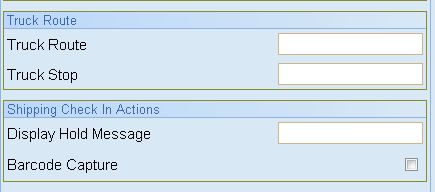

Truck Routing and Shipping check in Actions are normally left unchanged. At this time we have no reason to use them for Wal-Mart.

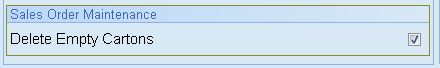

Shipping Maintenance is the removal of unused Carton ASN Numbers. This is option is only beneficial when scanning cartons and adding more than one item to a box. If you are using Faro Quick Complete this option should have no effect. It also would have no effect if you have a One for One item to Carton ASN or Carton N of M labels.

But if you asked for 12 labels and you only used 8 then the following check box removes unused labels from the system and prevents them from uploading. When Sending EDI this checkbox should always be checked. For Wal-Mart this is highly recommended and should be checked all the time.

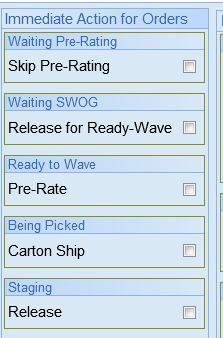

Immediate Action Boxes normally all boxes are un-checked unless staging is being utilized. Check Release will released from staging for shipping.

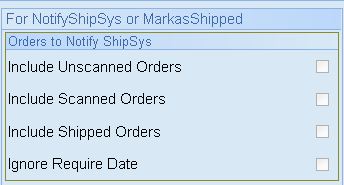

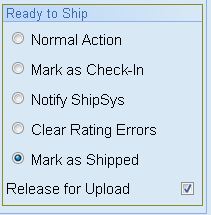

Now we get into our events and when to fire them for our shipping processes. Unless you are only trying to update the order the following is the proper settings. Upon Clicking Mark as Shipped the ability to add a ship date becomes available. If any other option is picked you cannot add the ship date at this time. With these settings in the picture below if all comforms to the rules your order is uploaded and removed from the active Sales Orders listing. It will then be available for viewing in history only using these settings and no modifications can then be made after you hit the submit button.

Shipping Markings are normally not needed for Wal-Mart and are left Unchecked.

If any options are picked it would Include Shipped Orders, Ignore Require Date.

Special Note:::If you are shipping Multiple orders it is highly recommended you pick Include Scanned Orders and leave Include Unscanned Orders blank.

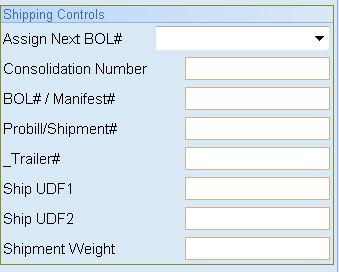

And the last part is the additonal Data required for EDI and should be entered here in the last options. Each will be discussed to aide you proper data entry

If your are using the the Master BOL screen the only option you may need is the Probill/Shipment# at this time. Though it can be added in the Master BOL Screen if know ahead of time. Trailer Number is optional but can be used for historical data. We do not send trailer number in Wal-Mart EDI. The Consolidation and the BOL Number should be already set before you got to this point. If not, then enter it here. MSY and Walmart expect a valid VICS BOL Number and Valid Consolidation Number with check Digits. It is highly recommended that the Master BOL Screen or the BOL Screen in Accellos be used to enter these numbers.

SHIPMENT NUMBER GENERATION

ProBill#/Shipment# background knowledge.

Normally we do not know the PRO Number (Shipment Number) or we may not ever know it. Shipment Numbers if hand generated should always be started with the carrier's 4 digit SCAT code. For example if the shipment is being sent via LAS VEGAS LOS ANGELES EXP the SCAC code will then begin with LVLA the proceeding part of the Shipment Number should be the date in Ansi Format Jan 29,2013 would be 20130129 and finally if multiple shipments go on one day for the same client then a counter number. So the first and second shipments utilizing LVLA would be created as LVLA201301291 AND LVLA201301292

Last updated Jan 29,2013 Faro IT Dept.